Harvard Professor Joanna Aizenberg shows David Pogue the Nepenthes Pitcher Plant, a carnivorous plant whose slippery surface inspired a non-stick material invented by her lab.

Slippery Surfaces

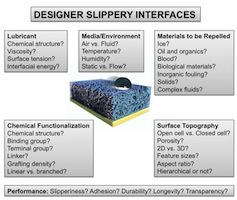

Unwanted surface interactions are a limiting factor nearly everywhere liquid is handled or encountered: they create drag in transport systems, trigger blood clotting, nucleate aircraft icing, and promote biofouling. Despite intensive study, state-of-the-art repellent surfaces have remained poorly suited for many substances, environments, and budgets. Inspired by the carnivorous pitcher plant, we have invented a fundamentally different conceptual approach to surface design that avoids the inherent limits of current strategies. Based on this approach, we have created surfaces that show almost perfect slipperiness toward polar and organic liquids, complex substances such as blood, oil, and ketchup, a genetically diverse range of bacteria and algae, and solid materials such as ice, dust, and insects. The surfaces can be optimized to function under extreme conditions, adapt to stimuli, and self-heal, and can be constructed from a variety of low-cost materials and applied to surfaces as diverse as medical tubing, planes, and refrigerators.

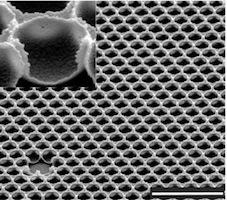

Our approach comes from the same concept the pitcher plants use to make insects slide down their leaves into their digestive juices. We infuse a porous substrate with a lubricating fluid such that the overlying film, rather than air or solid, serves as the slippery interface. Based on extensive theoretical and experimental characterization, we have defined materials requirements for the lubricant to form a locked-in, stable, inert surface. These surfaces outperform state-of-the-art surfaces in scope (water, hydrocarbons, crude oil, blood, ice, bacteria), liquid mobility (contact angle hysteresis <2.5o), resilience (recovery within 0.1-1 s); and pressure tolerance (up to ~676 atm). Since low-surface-energy porous solids are abundant from small to large sacles, highly omniphobic surfaces can be easily generated without specialized fabrication facilities.

Currently our group is developing this technology to meet emerging needs in biomedical fluid handling, fuel transport, antifouling, anti-icing, optical imaging, harsh environments, and other areas.

See SLIPS in action by following the links below:

Repelling crude oil

SLIPS self-healing

No blood left behind

Repelling insects and jam

Intelligent ant avoids SLIPS

SLIPS says "no" to a spray paint graffiti

No stickers on outdoor signs!

Ice repellence

No frost formation at T=-2C

Rapid defrosting of after deep freezing

A slipperier ice cube tray

The full collection is found here.

Stay tuned: more movies and demonstrations to come!

Interviews:

"The Makers" of The Mind of the Universe features Professor Aizenberg, International science documentary series, VPRO, May 21, 2017.

Nova episode on Making Stuff Wilder, October 23, 2013.

Deadly pitcher-plant inspires super slippery nano-surface, Reuters, February 6, 2012.

“Extreme Biomimetics” talk by Professor Aizenberg, Disruptive Ideas, TEDxBigApple, New York, February 4, 2012.

“Slippery when wet (or anytime)”, CBC interview with Professor Aizenberg, October 8, 2011.

Material World, BBC interview with Professor Aizenberg, September 21, 2011.

In the news:

Slippery liquid surfaces confuse mussels to stop them from sticking to underwater structures, Harvard press release, August 17, 2017.

ARPA-E Making Progress Toward Achieving Mission, Report by the National Academies of Sciences, Engineering, and Medicine, June 13, 2017.

Creating a slippery slope on the surface of medical implants, Harvard press release, November 1, 2016.

An unobstructed view into the human body, Harvard press release, September 26, 2016

Harnessing engineered slippery surfaces for tissue repair, Harvard press release, May 18, 2016.

Mid-Atlantic Seabed Drilling Expedition, BBC Science in Action podcast (starting at 14:08 minutes), October 23, 2015.

Super-slick material makes steel better, stronger, cleaner, Harvard press release, October 20, 2015.

The secrets of secretion, Harvard press release, June 22, 2015.

What Is ARPA-E Up to Now?, Innovation, May 2015.

Artificial membrane system uses fluid-filled pores for smooth moving, Materials 360, April 9, 2015.

Literally Nothing Will Stick To This New Slippery Surface, Fast Company, March 27, 2015.

Fabrics of Life, Nature, Outlook, March 25, 2015.

Pores for thought over separation issues, Materials Today, March 10, 2015.

Gating mechanism under pressure, Nature, News and VIews, March 5, 2015.

Fluid–filled pores separate materials with fine precision, Harvard press release, March 5, 2015.

New silicone infused with silicone oil = super-slippery, and proven to keep bacteria from growing on medical tubing, Reddit, February 20, 2015.

SLIPS team heads to Capitol Hill, Harvard press release, February 12, 2015.

Novel non-stick material joins portfolio of slippery surface technologies, Harvard press release, February 10, 2015.

Wyss Institute launches SLIPS company, Harvard press release, October 29, 2014. Read more at SLIPS Technologies.

Carnivorous Plant Inspires Anticlotting Medical Devices, Scientific American podcast, October 15, 2014.

Slippery When Coated: Helping Medical Devices Prevent Blood Clots, NPR, October 12, 2014.

Bioinspired coating for medical devices repels blood and bacteria, Harvard press release, October 12, 2014.

Super-Slick Material Keeps Ice From Forming, Technology Review, July 2, 2014.

Scientists Modify Cotton and Polyester to Display Repellent Properties, The Crimson, February 26, 2014.

Stain-free, self-cleaning clothing on the horizon, Harvard press release, January 13, 2014.

Pulling On The Shade, American Scientist, September 1, 2013.

New coating turns ordinary glass into super-slippery glass, Harvard press release, August 2, 2013.

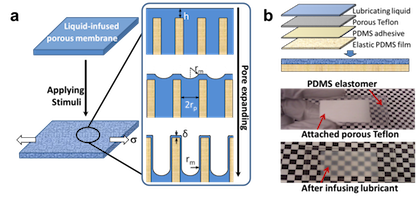

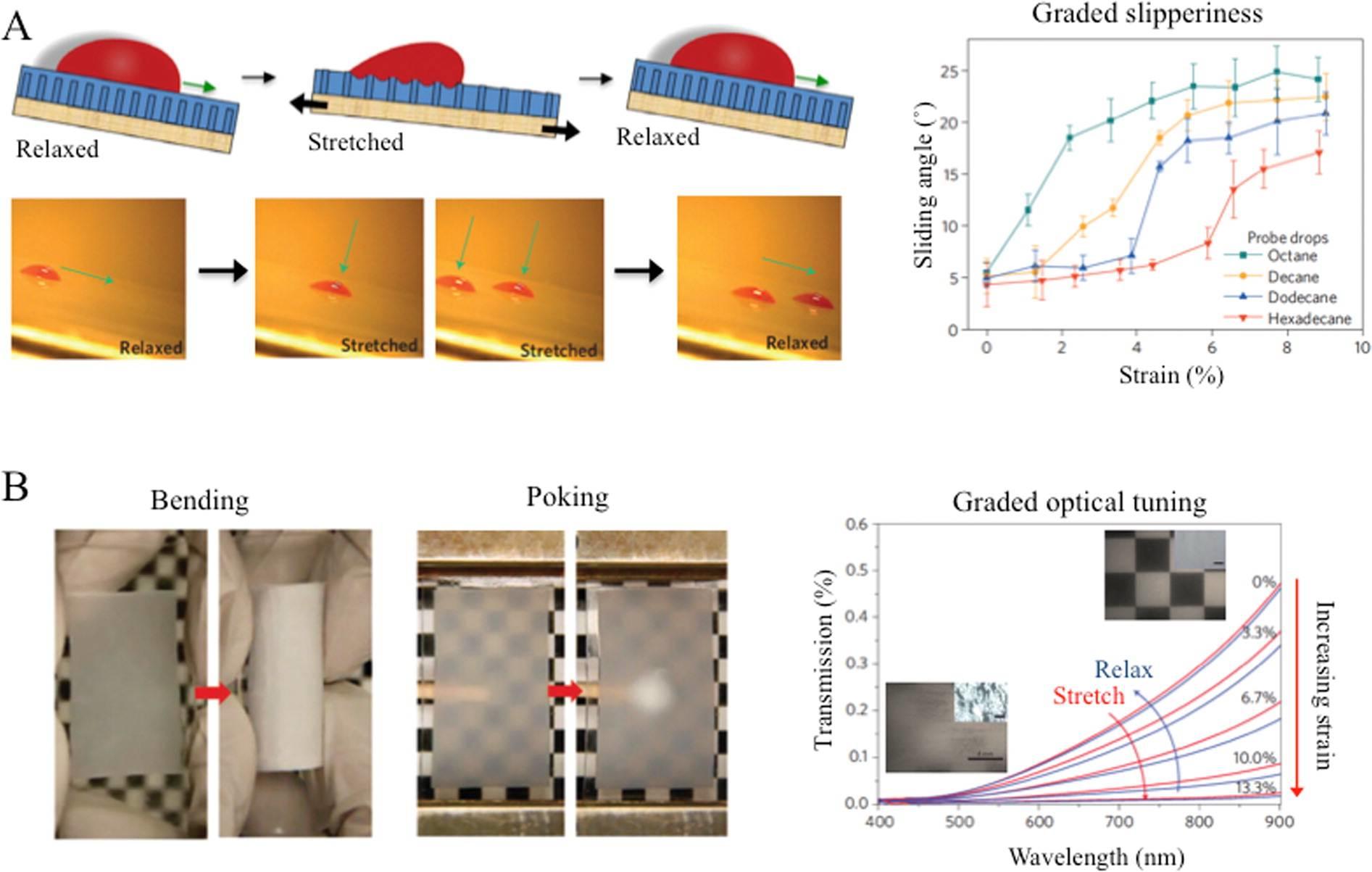

Fluid-Infused Porous FIlms Dynamically Adjust Transparency and Wettability, Materials 360, April 22, 2013.

Scientists Design New Adaptive Material Inspired by Tears, Popular Mechanics, April 17, 2013.

Morphing 'fabric' shifts shape to repel or grip water, New Scientist, April 9, 2013.

New material can halt runny liquids on demand, BBC, April 9, 2013.

Cry me a river of possibility: Scientists design new adpative material inspired by tears, Harvard press release, April 8, 2013.

Ice-Phobic Surfaces that are Wet, ACS Nano, August 9, 2012.

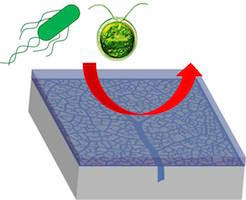

SLIPS Blitz Biofilms, Nature, August 9, 2012.

Harvard scientists' breakthrough could stop biofilm formation, Food Production Daily, August 9, 2012.

SLIPS liquid repeller is inspired by carnivorous plants, enemy to insects and graffiti artists alike, Engadget, August 3, 2012.

Super slippery surface prevents biofilms, PNAS, July 31, 2012.

New coating evicts biofilms for good, Harvard press release, July 30, 2012.

Ice Curbs, National Science Foundation's Discovery Files (podcast), June 27, 2012.

'Ice-Phobic' Airplane Wings, Wall Street Journal, June 22, 2012.

SLIPS receives a 2012 R&D 100 Award from R&D Magazine, honoring it as one of the 100 most technologically significant products of the previous year. June 20, 2012.

No Scraper Required: Ice Rolls Off Metal, Discovery, June 16, 2012.

Slippery Coating Keeps Metals Frost-Free, Chemical and Engineering News, June 15, 2012.

Keeping Metal Surfaces Ice, Frost Free, The Hindu, June 14, 2012.

Ultra-Antifreeze Keeps Ice From Even Forming, Smithsonian, June 12, 2012.

A new spin on anti-freeze, Harvard press release, June 11, 2012.

Super-slippery material could mean end to having to wait for ketchup, The Telegraph, November 13, 2011.

Slippery Slope: researchers take advice from carnivorous plant, Harvard press release, September 21, 2011.

Slippery when wetted, Nature News and Views, September 21, 2011.

Carnivorous plant inspires super slippery material, New Scientist, September 21, 2011.

Pitcher plant inspires super slippery surface, Chemical and Engineering News, September 21, 2011.

Ketchup bottle problems solved, The Telegraph, November 13, 2011.

Carnivorous plant shows its slippery side, Financial Times, September 30, 2011.

A great non-friction story: Researchers create ‘world’s most slippery surface’, Daily Mail, September 22, 2011.

Scientists create wonder material, Metro Herald, p. 10, September 22, 2011.

Copied from pitcher plants; destined for ketchup bottles, Popular Science, November 14, 2011.

Pitcher plant perfect, Nature Chemistry, vol. 3, pp. 834, October 24, 2011.

Pitcher plant inspires ultimate non-stick surface, Chemistry World, September 22, 2011.

Plant technology used to create super-repellent material, The Engineer, September 26, 2011.

Flesh-eating plant inspires super-slippery material that repels everything, Discover Online, September 21, 2011.

Invention Solves Ketchup Dilemma, The Harvard Crimson, November 20, 2011.

Source: Nature

Michael Nosonovsky of the University of Wisconsin-Milwaukee: "The development of SLIPS typifies two themes that are likely to dominate the field of biomimetic and functional surfaces in coming years."

Source: C&EN (ACS)

Philippe Brunet, an expert on omniphobic materials at France’s University of Paris Diderot, says he is impressed by the innovative strategy. “In my opinion, this study does not simply represent an improvement in liquid-repellent surfaces, but rather a revolution in the field,” he says. “I am sure many researchers reading this paper would think as I do: ‘I wish I would have thought about these surfaces before.’”

Source: Chemistry World (RCS)

"This really is a new direction," says Steven Bell, director of innovative molecular materials at Queen's University Belfast, UK. "Many of us have been working on improving the durability of 'lotus effect' materials but this now offers us an alternative way to try to reach the same objectives."

Source: ABC (Australia)

Professor Robert Short, director of the Mawson Institute at the University of South Australia, says the results are highly impressive and the simplicity of the approach is particularly striking.

"The combination of solids and liquids uses capillary action to bring lubricant to the surface of nano/microengineered structures," Short says.

"Furthermore, the ability of the surface to 'heal' sets it apart from other cutting-edge approaches."

Source: Discover

Walter Federle from the University of Cambridge, who discovered the structure of the pitcher plant’s peristome, says,“It’s really exciting to see that this principle has inspired the authors and allowed them to develop something that could prove extremely useful.”

Source: New Scientist

"It's interesting that it combines self-lubrication, self-healing and self-cleaning, which are different

processes," says Michael Nosonovsky of the University of Wisconsin-Milwaukee. "It's a new type of

smart material."

The full collection is found here.

Stay tuned: more movies and demonstrations to come!